Fixing systems

Fixing systems

Quick release or high risk protection – combine fixings, posts and panels to create a machine guarding system that fits your needs. All fixing systems have captive mountings which will remain attached to the panels and posts even when the guard is disassembled.

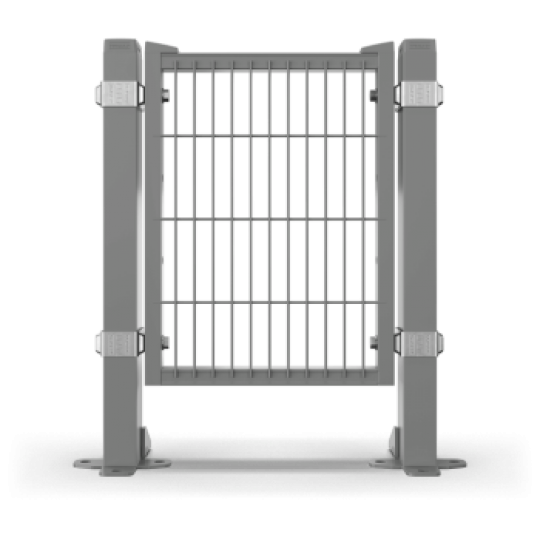

The Smart Fix system is best–selling safeguard system. This versatile machine guard is extremely durable and fits most applications. The Smart Fix system can easily be combined with other systems, such as Rapid Fix and Strong Fix to create unique, suitable solutions. Choose among a wide range of doors, locks and accessories to customize your installation. The Smart Fix system is heat–resistant and it’s tested to withstand an impact of 2 000 joules in the most common sold combination with the ST20 mesh panels. This strong and flexible Smart Fix system is easy to assemble and can be combined with any of the machine guarding panels in mesh, steel or polycarbonate. The bracket is easily mounted to the 60×40 mm posts, tightened to the post with an M8 bolt on the inside of the fence and can easily be moved up and down to adjust for uneven floors. The bolts will be held captive to the panels even when the system is disassembled, fulfilling the requirements and standards for machine guarding.

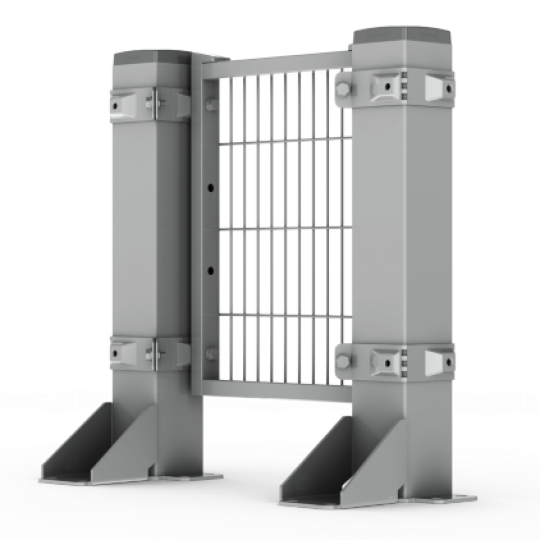

Strong Fix is strongest machine guarding system. It has been developed and tested to endure the harshest environments.

For heavy industrial environments and where there is a high risk for an impact, the Strong Fix system is the perfect solution. Based on the heavy 80×80 mm posts combined with a strong bracket and the ST30 mesh panels, the system is tested to withstand an impact of 3 000 joules in our test center, and even higher energies can be withstood. The brackets are easily mounted to the posts and tightened with an M8 bolt on the inside of the fence. Move the brackets up and down on the post to adjust for uneven floors. The Strong Fix system can be mounted with double ST20 panels, creating a super strong machine guard – withstanding an impact of 8 180 joules! – depending on the quality of the floor it is fixed to.

Rapid Fix is cleverly designed machine safety system that offers quick and easy access to the hazard zone.

The updated Rapid Fix bracket is faster and easier to install and at the same time more impact resistant. Together with the ST20 mesh panels, the updated Rapid Fix system is tested to withstand an impact of 1 600 joules. The system is easily disassembled from inside the cell, using a special tool, Torx with pin, to release the panels. To re–assemble the panel, slide in the lower fixing into the slot and click the panel in place. Rapid Fix offers a fast and flexible access to the machine.

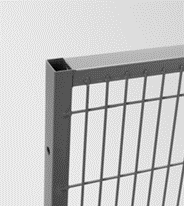

Safe Fix is a good option for creating cells without gaps, suitable for welding applications or where there is a splash risk.

The Safe Fix bracket adjoins the panels in front of each post, removing the gap between panels and posts. Together with the steel sheet panels, you can create a fully–covered machine guard for applications with welding or splash risks. With the kit Safe Fix junction, the bolts are held captive in the guard even when the system is disassembled, fulfilling the requirements of the Machinery Directive. Together with the URSP steel sheet panels, the Safe Fix system is tested to withstand an impact of 309 joules.